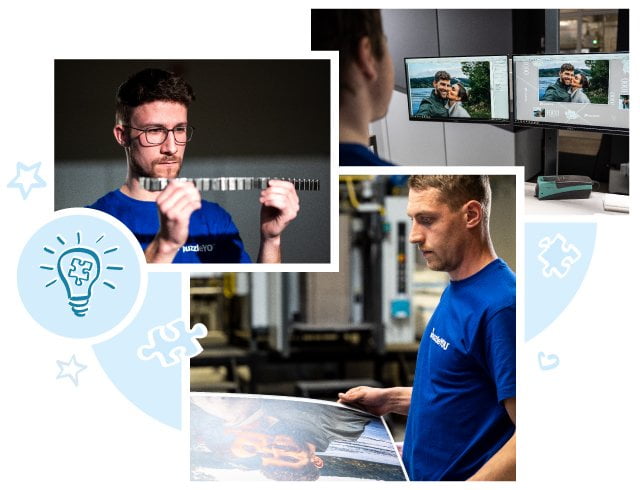

Production process - How your photos are turned into a jigsaw puzzle

Producing photo puzzles is not as easy as you would probably think. Comprehensive expertise about material composition, cardboard- and paper processing or the handling of adhesives is essential. Especially the main factors for success, such as the ambient temperature and the atmospheric humidity, are in practice not always easy to handle. Together with our knowledge, modern digital printing and hand-made punching devices take care that you will enjoy our puzzles for many years.

How do we turn your photo into a jigsaw puzzle anyway? First, we print your photograph or photo collage on sustainable photo paper. Then we adhere it to our specifically for us designed puzzle cardboard. Within the punching process, we punch the puzzle pieces with a weight of over one ton. Finally, a special separation machine disassembles your puzzle into its individual pieces before we fill them into a polybag. At the end it becomes romantic – At the so called „marriage“, the individual puzzle boxes, which have been made in a separate production line, are filled with the bags with puzzle pieces.

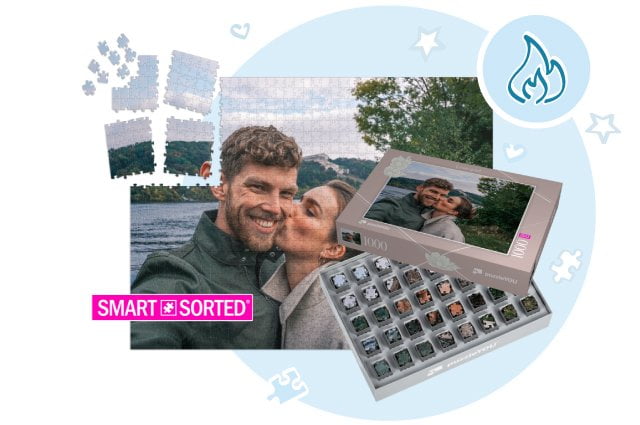

SMART SORTED® - The puzzle revolution from in-house production

puzzleYOU has been producing classic photo puzzles in-house for years. Our die-cutting specialists are experts in their field and are always venturing into new projects to create the most beautiful puzzles imaginable. How does the production process for the cleverly pre-sorted puzzle segments of the worldwide novelty SMART SORTED work? With ingenuity, expertise and great attention to detail. Innovative die-cutters and special machines sort SMART SORTED cleverly and neatly arranged in your puzzle box. Each of the 40 boxes contains 25 puzzle pieces waiting to be put by you. You control the level of difficulty. SMART SORTED by puzzleYOU – for the most personalised puzzle experience ever.

-

How is a puzzleYOU jigsaw made?

puzzleYOU has been producing high-quality personalised jigsaw puzzles in-house for more than a decade. Skilled employees apply our quality standards when creating puzzles and games with your photos. Our puzzles are produced using the "print-on-demand" process and are produced individually for each of our more than 2 million satisfied customers.

-

What is puzzleYOU's quality promise?

High-quality, safe, durable and resistant personalised puzzles and games are produced quickly, so you can have your self-designed photo puzzle in your hands within days. Our puzzles and games are certified and our children's puzzles in particular meet the strict requirements of the toy standards. To guarantee our customers the highest quality, we place special value on producing our puzzles in-house.

-

Are our jigsaw puzzles environmentally friendly?

At puzzleYOU, we pay great attention to sustainability. Our puzzle board and shipping boxes are made of 100% recycled paper. Because we produce a puzzle only after it has been ordered, we avoid wasting material, unnecessary transport and energy-consuming storage. We also use green electricity for production and are working to make our products completely plastic-free in the future. Since 2021, for example, we no longer have plastic foil around our boxes, which make sus save up to 4 tonnes of plastic every year.